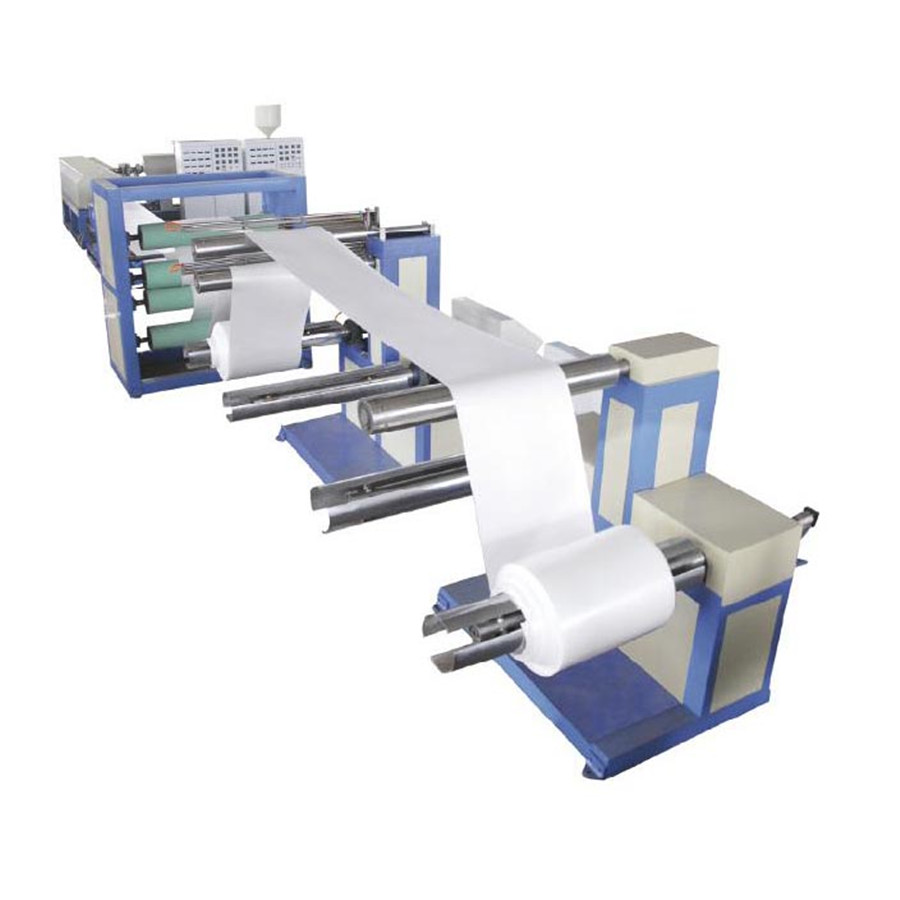

PS fast food box line

Ⅰ 105/120 PS foam sheet extrusion line inosanganisira zvinotevera zvikamu

Ⅱ Main parameters

| Item | Unit | Parameter | Remark |

| Model | FS-FPP105-120 | ||

| Inoshanda zvinhu | GPPS granule | ||

| Ukobvu hwechigadzirwa | mm | 1-4 | |

| Kufara kwepepa | mm | 540-1200 | |

| Furo rate | 12-20 | ||

| Kurema kwechigadzirwa | Kg/m³ | 50-83 | |

| Thermal conductivity yechigadzirwa | W/mk | 0.021-0.038 | |

| Output | kg/h | 150-200 | |

| Rated power | Kw | 200 | |

| Magetsi | chikamu chetatu 380v/50Hz | ||

| External dimension | mm | 26000×7000×3000 | |

| Complete muchina uremu | Ton | About12 |

Ⅲ Chati yekugadzira inoyerera

A.Automatic feeding system

1. Nzira yekudyisa

Spiral feeding

2. Main parameters

| Hopper kugona kwemusanganisi (kg) | 300 |

| Motokari Simba remusanganisi (kw) | 3 |

| Kudyisa simba remufudzi (kg/h) | 200 |

| Motokari yemagetsi ye feeder (kw) | 1.5 |

B. The first stage extruder

1. Sikiri uye mbiya zvinhu

38CrMoAlA nitrogen kurapwa

2. Main motor style

AC-motor ine frequency converters

3. Speed inoderedza

Extruder yakatsaurirwa inoderedza, yakaoma zino pamusoro, yakakwirira torque, uye yakaderera ruzha

4. Heater

Aluminium casted hita, solid-state relay contactless kubuda, yakangwara tembiricha controller tembiricha

5. Technical parameters

| Kutyaira mota simba (kw) | 55 |

| Diameter of screw bolt (mm) | Φ105 |

| L/D chiyero che screw bolt | 34:1 |

| Max rev of screw (rpm) | 30 |

| Nhamba yenzvimbo dzekupisa | 10 |

| Kupisa simba (kw) | 40 |

C.Kufuridzira agent jekiseni system

1. Mhando yepombi

Plunger mhando yakakwirira kurongeka uye yakakwira yekuyeresa pombi, kuenzanisa nzira imwe-vhavha yekudzora, iyo jekiseni vhoriyamu inodzorwa nekusimudza plunger.

2. Main michina parameters

| Mhando yekufuridza agent | butane kana LPG |

| Kuyerera kwepombi yemamita | 40 (L) |

| Jekiseni high pressure | 30 (Mpa) |

| Pressure gauge | 0-40 (Mpa) |

| Motor simba | 3 (kw) |

D.Non-stop muchina hydraulic otomatiki kutsiva sefa system

Hydraulic inokurumidza mambure ekuchinja mudziyo

Main parameters

| Oiri pombi injini simba | 4 (kw) |

| Pombi yemafuta max pressure | 20 (Mpa) |

| Sefa mambure akawanda | 4 (chidimbu) |

| Kupisa simba | 8 (kw) |

E.Danho rechipiri extruder

1. Chikuro uye mbiya zvinhu

38CrMoAlA nitrogen kurapwa

2. Main motor style

AC-motor ine frequency converters

3. Speed inoderedza

Extruder yakatsaurirwa inoderedza, yakaoma zino pamusoro, yakakwirira torque, uye yakaderera ruzha

4. Heater

Aluminium casted hita, solid-state relay contactless goho, yakangwara tembiricha controller tembiricha, Inotonhorera mudziyo wemvura mune hita.

5. Kutonhodza uye tembiricha-kuderedza maitiro Kutenderera kutonhora kwemvura, otomatiki bypass system.

6. Technical parameters

| Kutyaira mota simba (kw) | 55 |

| Diameter of screw bolt (mm) | Φ120 |

| L/D chiyero che screw bolt | 34:1 |

| Max rev of screw (rpm) | 30 |

| Nhamba yenzvimbo dzekupisa | 13 |

| Kupisa simba (kw) | 50 |

6. Technical parameters

F. Extruder musoro uye mold

1. Chimiro

Round of the extruder head, mold muromo unogona kugadzirisa, musoro uine pressure gauge uye pressure yekubuda alarm kifaa.Hita yemusoro ine kutonhora kwemvura .

2.Zvinhu

Yemhando yepamusoro chishandiso simbi, inopisa-yakagadziriswa, inoyerera chiteshi chepamusoro kushata: Ra0.025μm

3. Main data data

| Diameter ye mold orifice | Maererano nechibvumirano chekuraira |

| Huwandu hwenzvimbo dzekudzora tembiricha | 2 |

| Kururama kwekutonga kwekushisa | ±1 (℃) |

| Kupisa simba | 5 (kw) |

G. Kuumba kutonhora nekucheka system

1. Kuumba chimiro: kuumba mbiya

2.Cooling style:kuumba mbiya inotonhorera nemvura uye yekunze mhepo-mhete

3.Structure:kuumba mbiya, banga rekucheka uye rack zvikamu

4.Main technical parameters

| Kuumba saizi yebhari (mm) | Maererano nechibvumirano chekuraira |

| Simba rekuvhuvhuta (kw) | Mitsara mitatu 0.55 |

H.Kudhonza hurongwa

1.Kudhonza maitiro:ina-roller parallel dhonza, compress nemhepo drive

2.Kutyaira mota fomu: AC-motor, frequency kutendeuka velocity modulation, kukurumidza kuderedza inoshandura kukurumidza

3. Main parameters

| Kudhonza roller huwandu (chidimbu) | 4 |

| Kudhonza saizi yeroller (mm) | Φ260×1300 |

| Motokari magetsi (kw) | 1.5 |

I. Electrostatic elimination system

Adap tod tod type ion rod electrostatic elimination system, inoshanda volt iri 7KV pamusoro, inogona kuburitsa mhepo ine simba uye ine simba ion mhepo, kunyatsobvisa njodzi yemagetsi.

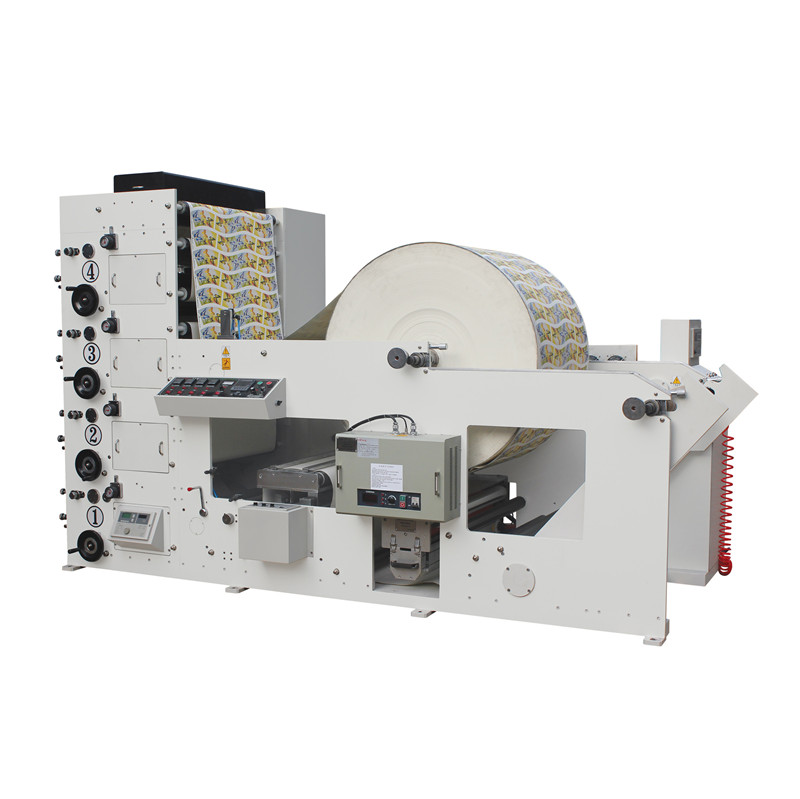

J.Winding system

1.Form

Kaviri-ruoko air shaft mhando

2.Main technical parameters

| Coiling uremu (kg) | Maximum40 |

| Coiling dhayamita (mm) | Max 1100 |

| Kudzora kureba | Meter counter control, gadzirisa kureba |

| Kutyaira mota | Torque mota 8n.m×2 seti |

K. Electric control system

Kupisa kunodzora kabhineti yekutanga nhanho extruder: imwe seti

Kupisa kunodzora kabati yechikamu chechipiri extruder: seti imwe

Winding control cabinet: imwe seti